- KISWEL is about connecting values

ALL PRODUCTS

Line-Up

- Titanium Powder

-

We, KISWEL started to supply the high purity of HDH Ti powders including Ti-6Al-4V alloy powders by development of the own unique technologies for the precise control of powder purity by research.

▶ Titanium powderTitanium powder is usually manufactured as near or less than 350 μm in size and used as the raw materials for production of various titanium parts with complicated shapes by consolidation process such as sintering, hot isostatic pressing(HIP) and metal injection molding (MIM)

▶ Production methods of titanium powderTitanium powders can be manufactured by crushing by hydride-dehydride(HDH) treatment and gas atomization processes, among them the HDH’s product takes a possession over 90% among global consumption because of its cheap cost of the process. To magnify an application fields for Ti powders, the control of powder purity is a key-technology.

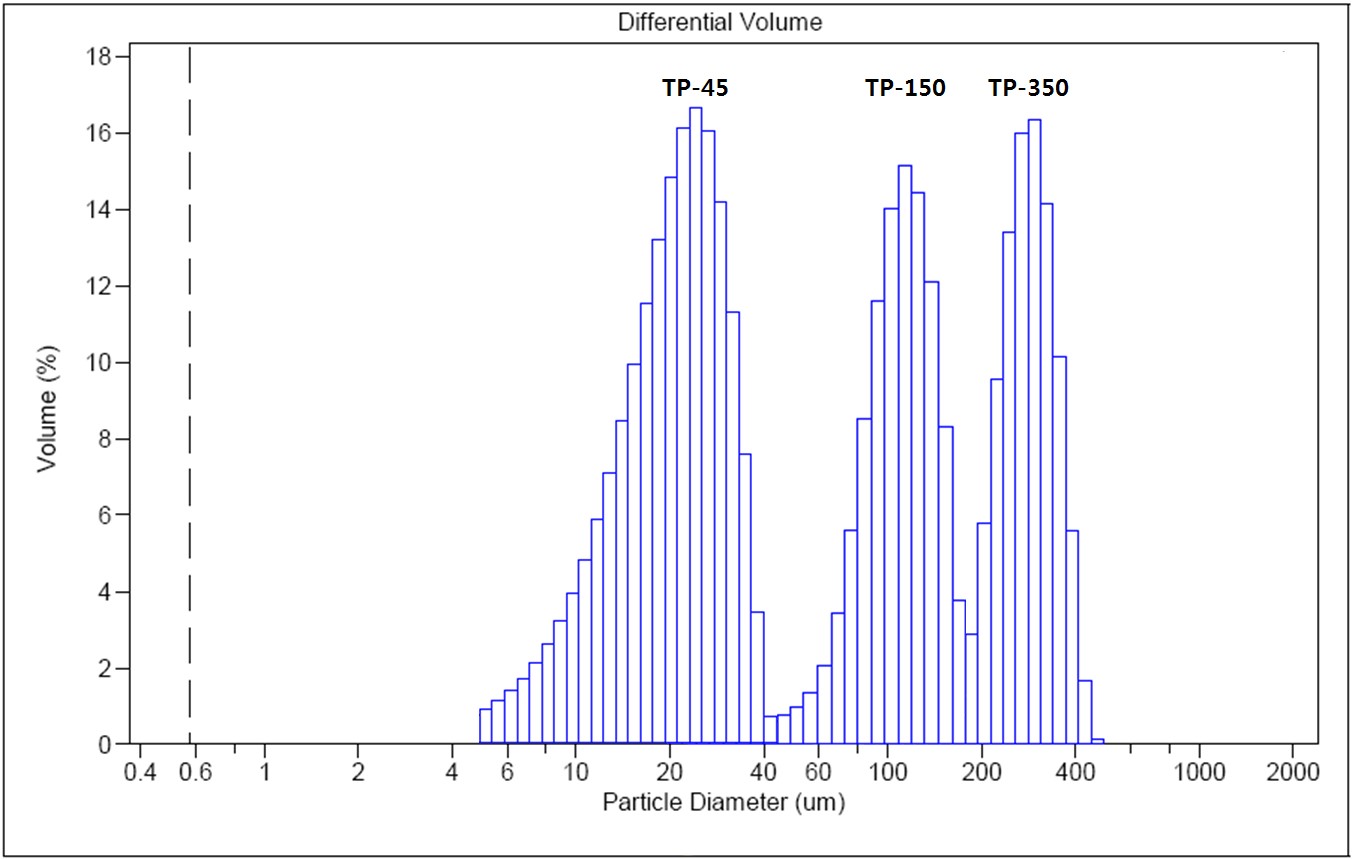

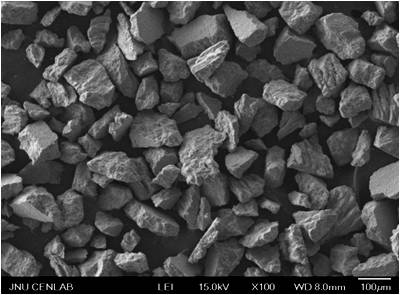

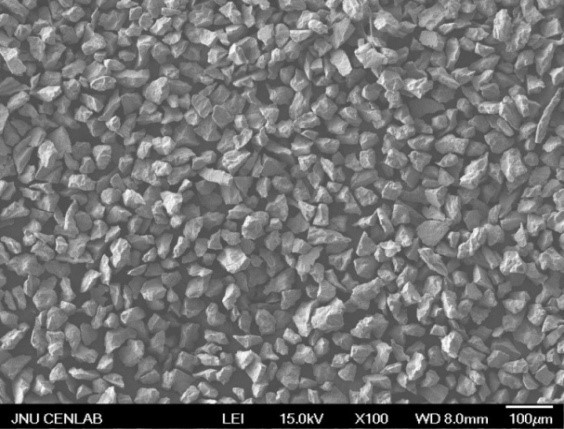

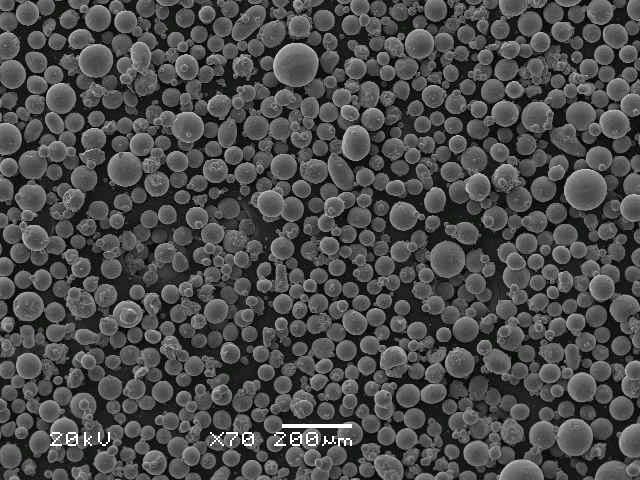

▶ Specifications and Powder Shape of KISWEL’ productsPowder SpecificationsPowder Specifications Materials Type Models Size (μm) Chemical composition, wt.% max. Ti O N H C Ci Fe Si Al V Pure Ti Irregular TP-350 < 350 Bal 0.20 0.02 0.01 0.03 0.05 0.05 0.02 - - TP-250 < 250 Bal 0.2 0.02 0.01 0.03 0.05 0.05 0.02 - - TP-150 < 150 Bal. 0.20 0.02 0.01 0.03 0.05 0.05 0.02 - - 0.30 0.02 0.01 0.03 0.05 0.05 0.02 - - TP-45 < 45 Bal. 0.35 0.02 0.01 0.03 0.05 0.05 0.02 - - Ti-6A-4V TP-350 < 350 Bal. 0.20 0.02 0.01 0.03 0.01 0.15 0.02 5.7~6.8 3.5~4.5 TP-250 < 250 Bal. 0.20 0.02 0.01 0.03 0.01 0.15 0.02 5.7~6.8 3.5~4.5 TA-150 < 150 Bal. 0.20 0.02 0.01 0.03 0.01 0.15 0.02 5.7~6.8 3.5~4.5 0.30 0.02 0.01 0.03 0.01 0.15 0.02 5.7~6.8 3.5~4.5 TA-45 < 45 Bal. 0.35 0.02 0.01 0.03 0.01 0.15 0.02 5.7~6.8 3.5~4.5 Pure Ti Spherical TPS-150 < 150 Bal. 0.15 0.02 0.01 0.03 0.05 0.05 0.02 . . TiH2 Irregular HTP All Bal. 0.50 0.40 3.80 0.05 0.05 0.05 0.02 - - Range of Particle SizeAngular Powder-

TP-150

-

TP-45

Spherical Powder

(After Spherification Process)-

TPS-150

▶ TiN powderWe produce TiN powder with low manufacturing cost and applicable PM and MIM process.

TiN powder

▶ Applications for Titanium PowderTitanium powder can be applied in various industries for the production of 3D shape of small parts such as jewelry and smart phone and high strength large parts such as automobile engine, military, aircraft and so on.

▶ Parts by Pure Ti Powder-

Smart phone

-

Bio-implant

-

Jewelry

▶ Parts by Ti-6Al-4V Powder-

Automobile Engines

-

Military

-

3D-printing

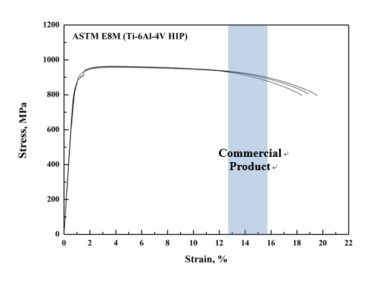

▶ Ti HIP part of mechanical properties- In particular, we confirmed that tensile properties(ASTM E8M-S5 sample) of consolidation part made from Ti-6Al-4V powders were 960MPa in tensile strength and 18.5% in elongation, which are satisfied with ASTM-B988-13 Grade 5 PM (>895Mpa, >10%).

Ti HIP part of mechanical properties Mechanical properties Yield Strength

(MPa)Tensile Strength

(MPa)Elongation

(%)Reduction of Area

(%)Hardness

(Hv)Ti6Al4V HIP sample 860 960 18.5 34 320 Grade 5 100M

(ASTM B988-13)828(min) 895(min) 10(min) 25(min) -

The stress-strain curves byHIP samples with KISWEL’s Ti-6Al-4V alloy powder

▶ ContactContact Contact E-mail Tel Central Technology Institute Researcher Su-in Lee titanium@kiswel.com +82 55 269 7269 -